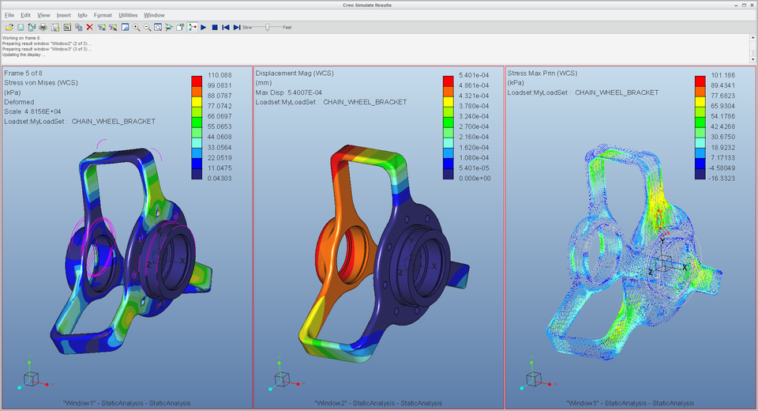

5-Step Guide to Running a Static Analysis in Creo Simulate

- Step 1: Assign a material. Before you run an analysis, you need to assign a material to your model. …

- Step 2: Apply constraints. Next, follow these steps to apply constraints to your part. …

- Step 3: Apply a load. …

- Step 4: Run the Analysis. …

- Step 5: Viewing the results.

Just so, What is Creo Simulation?

Creo Simulate is a multi-discipline CAE (Computer Aided Engineering) tool with which you can simulate the physical behavior of a model and understand and improve the mechanical performance of your design. … A limited functionality, trial version called Creo Simulate Lite is provided with Creo Parametric.

What types of analysis can be done if couple Creo Parametric mechanism with Creo Parametric simulate structure? Perform structural, modal and thermal analyses directly within Creo Parametric. With Creo Simulation Live engineers can analyse their designs in real-time directly within the Creo Parametric using ANSYS’ Discovery Live technology. Structural, modal and thermal live analyses are supported.

Similarly, How do you do Creo Simulation?

How do I create a flow analysis in Creo?

How do you do Creo simulation?

What is the difference between simulation and analysis?

As nouns the difference between simulation and analysis

is that simulation is something which simulates a system or environment in order to predict actual behaviour” while analysis is (countable) decomposition into components in order to study (a complex thing, concept, theory).

Is Creo A analysis software?

Simulation and analysis is fast and easy with Creo

Some of our solutions offer design guidance while others offer a comprehensive set of capabilities that allow you to analyze and validate the performance of your 3D virtual prototypes.

What can be done in Creo?

With Creo Parametric, and its extensions, you can create, analyze, view, and share designs downstream using 2D CAD, 3D CAD, and parametric and direct modeling capabilities.

What is Creo flow analysis?

Creo Flow Analysis (CFA) is a computational fluid dynamics tool used to easily simulate fluid flow. This helps predict the performance of a system or product involving internal or external fluid flow and heat transfer.

Can Creo be used for analysis?

Simulation and analysis is fast and easy with Creo

Whether you are a design engineer or an analyst, PTC provides solutions fit for your needs. These suites of solutions allow you to test the stresses and loads under which your product will operate.

How do you use a moment in Creo simulate?

- Click Live Simulation > Moment. …

- Specify a name for the load, or use the default name.

- Select a surface on which you want to apply the moment load. …

- Select one the following options to specify the magnitude and direction of the load: …

- Select units of moment from the list or accept the default units.

Why are simulations better than formulas?

First, it is cheap because it uses random numbers generated rather than data that are collected. Second, it is much faster than traditional data collection, so tests can be run more quickly. Best of all, if the hypothesis or model is pretty solid, then the results of simulation statistics can approximate real results.

What are the different types of simulation models?

Simulation models can be generally classified into one of three major types, namely, continuous event simulation, discrete event simulation, and Monte Carlo simulation or Monte Carlo methods (MCM).

Why are simulation and calculations different?

Re: difference between the calculation by hand and simulatio

Hand calculation takes simple mos model (level 1) into consideration. On the other hand computer simulation takes complex model into consideration,while doing calculation. Difference betn results are very less than 5 to 10 %.

What is Creo and Ansys?

Creo Ansys Simulation seamlessly integrates the power of Ansys, the leader in engineering simulation, directly into Creo. Built specifically for designers and engineers, this easy-to-use, fully-featured, high-fidelity simulation tool leverages Ansys’ capabilities for thermal, structural, and modal analyses.

How different is Creo from SolidWorks?

The biggest difference between Creo and SolidWorks would be their complexity for users. SolidWorks is a much less complex option and has a quicker learning curve for beginners. Creo is a much more complex program and is aimed at the higher-end CAD market.

What is Pro Mechanica?

➢Pro/MECHANICA MOTION — a motion. analysis package that provides mechanism. modeling and mechanism design. optimization capabilities.

Is Creo hard to learn?

Due to its many capabilities and high functionality, first-time users often find Creo difficult to navigate, regardless of previous experience with other CAD software. There is so much to learn about what Creo’s features are and how to use them, that learning to use the software can be quite daunting.

Is Creo and Pro E same?

Creo is simply the latest version of Pro/E, which was launched under the new name back in 2011. Since the name change, there have been four major upgrades to Creo, with the latest, Creo 5.0, launching in March of 2018. Creo is not a single product, but a suite of tools that handle specific CAD tasks.

Is Creo better than SolidWorks?

Creo is much more stable and far superior to SolidWorks when it comes to top-down design and surfacing. Creo would also be a better choice for any project consisting of large assemblies. SolidWorks is primarily used for smaller scale and simpler design projects.