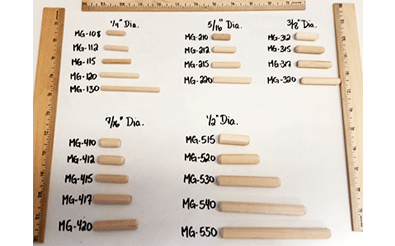

DOWEL PIN DIMENSIONS

| DOWEL PIN DIMENSIONS – METRIC | ||

|---|---|---|

| NOMINAL SIZE | PIN DIAMETER (A) | POINT DIAMETER (B) |

| 6 | 6.010 | 5.4 |

| 8 | 8.012 | 7.4 |

| 10 | 10.012 | 9.4 |

Just so, How strong is a 1 dowel?

Your 1″ dowel would be approximately 1/3 the strength of the 1.5″ dowels. Their weakest dowel had a safe load of 3,200# with an ultimate failure load of 5,000 – 6,000#. Therefore your safe load will probably be more than 1,000# and almost twice that before it would actually fail.

How deep should a dowel hole be? The holes to accommodate the dowels should each be drilled about 1/16 of an inch deeper than 1/2 of the length of the dowel section being used. Dowels 1 1/2-inches long are commonly used, so in this case, you would drill each of your doweling holes to 13/16 of an inch in length.

Similarly, How strong is a 1/2 inch dowel?

A 1/2″ dowel would be plenty, and I think a 3/4″ dowel (at 3-4″) would be able to hold me without breaking (200 lbs.) I would recommend 1/2″ since that would be plenty strong and still small enough not to be obvious for your display.

How strong is wooden dowel?

Test results show that dowels are the strongest method for creating this type of joint. The dowel joint in solid oak failed at an average of 650 pounds pressure, mortise and tenon joints failed at 500 pounds and biscuits failed at 325 pounds. Variations in the pressure at failure was less than 5 percent.

How much weight can a 1/2 inch dowel hold?

A 1/2″ dowel would be plenty, and I think a 3/4″ dowel (at 3-4″) would be able to hold me without breaking (200 lbs.) I would recommend 1/2″ since that would be plenty strong and still small enough not to be obvious for your display. (I am assuming that most of these guitars are under 20 lbs.

How much weight can a wooden stick hold?

Call it 50 to 60 pounds evenly distributed… If the rod is only held at one end and the weight is concentrated at the other then you may be successful at loading about 10–15 pounds before it breaks.

How strong is oak dowel?

Test results show that dowels are the strongest method for creating this type of joint. The dowel joint in solid oak failed at an average of 650 pounds pressure, mortise and tenon joints failed at 500 pounds and biscuits failed at 325 pounds. Variations in the pressure at failure was less than 5 percent.

Are dowels stronger than screws?

Dowel Strength

Dowel joinery is stronger than screw joinery. The increased glue surface caused by the glue deeply penetrating the wood gives the dowel more holding power. … Dowels also have superior holding power in modern composite materials such as particleboard and plywood.

How tight should a dowel fit?

Dowels can run a few thousandths of an inch larger or smaller than their specified diameter, leaving them tight or loose in the mating holes. Here’s an easy way to make sure that the dowels fit snug. For a 1⁄ 4 ” dowel, for example, drill a 1⁄ 4 ” hole in scrap. Test-fit the dowel in the hole.

How far apart should dowels be in concrete?

Dowels are typically spaced 12 inches apart either over the entire length of the joint or may be placed in clusters of 3, 4 or 5 that are centered over the wheel paths (as illustrated previously in figure 15).

Are birch dowels strong?

Usually, wood from trees like ash, oak, cherry, and birch are used to make dowels, as these woods are strong and reliable. Other hardwoods like poplar, beech, and mahogany are also used to manufacture dowels.

What size pull up bar for dowel?

4. Drill holes in the triangles I tried a 1.25” diameter wood dowel for the bar but it was too weak. ¾” diameter steel pipe works well with but I prefer wood. I found a 1.5” diameter maple dowel 36” long and used that for my chin up bar.

Are dowels better than screws?

Dowel joinery is stronger than screw joinery. The increased glue surface caused by the glue deeply penetrating the wood gives the dowel more holding power. … Dowels also have superior holding power in modern composite materials such as particleboard and plywood.

Do dowels need glue?

If the dowels fit their holes snugly, as they should, then any glue placed on the dowels themselves will be scraped outwards along the dowels when you insert them. For this reason, you should apply glue only in the dowel holes.

Are dowels stronger than pocket holes?

The dowel joints were 1.5x stronger than the pocket hole joints. I could have made the dowel joints stronger by using four dowels instead of two. Earlier tests indicate that such a joint should be nearly as strong as a mortise and tenon joint.

What weight can OAK support?

Maximum Compressive Strength

| Table material | Strength (Maximum load) / psi |

|---|---|

| Oak, White | 7440 |

| Mahogany | 6460 |

| Birch | 8170 |

| Fir, Douglas | 7230 |

Can MDF support weight?

How Much Weight Can an MDF Shelf Hold? According to thisoldhouse.com, an MDF shelf with a size of 3ft. (900mm) long x 1″ (25mm) thick x 12″ (300mm) deep and unsupported can hold 87 lbs. (40kg) of weight without sagging more than 1/4″ (6mm).

How much weight can a 1 inch plywood hold?

You can find 1-inch-thick fir plywood for use in heavy construction projects. Some will have tongue and groove patterns that lock together for even more strength. A 12-by-36-inch piece of 3/4-inch fir plywood can easily support 50 pounds.

Which is stronger dowels or pocket holes?

Mortise and tenons were twice as strong as pocket holes. That said, half as strong as a mortise and tenon joint is actually pretty good for something quick and dirty. … The dowel joints were 1.5x stronger than the pocket hole joints.

What are the disadvantages of using a dowel joint?

The main disadvantage is that they are weak. When it comes to tenon and mortise joints, the face grain cheeks of the tenon are completely in contact with the face grain side of the mortise. The glue also holds best in this situation.